SOLUTIONS > Industrial Automation > Control Platforms > Functional & Process Safety

Functional & Process Safety

GE Intelligent Platforms offers safety solutions specifically designed for process industry and factory automation applications. The process safety solutions include hardware features such as analog input validation, line fault detection, and output dynamic testing. To provide class-leading performance in all environments, the hardware can be operated between -40 and 70° C, are G3 conformal coated, and are resistant to 5G vibration and 30G shock. Software security features include programming security, programming change tracking, program validation with respect to language, coding, and references, and determination of trusted and safe data sources.

PAC8000 SafetyNet |

VersaSafe Machine Safety |

GMR |

|

|

|

SafetyNet is part of the PAC8000 range - specifically designed to meet the needs of the Process Industry. A rugged product, it can be used standalone in SIL 2 ESD or Fire & Gas applications - and if standard IO is mounted on the SafetyNet node, it can be used as a tightly Integrated Control and Safety System.

|

The VersaSafe distributed safety system provides a TUV-certified SIL 3 safety system that focuses on the critical control requirements of the production environment. By combining secure network connectivity, certified safety function blocks, an easy to use graphical programming environment, customers can efficiently integrate standards compliant safety capabilities while meeting increasingly stringent regulatory requirements.

|

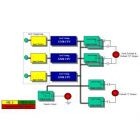

GMR offers unique flexibility in the way controllers and distributed I/O blocks can be arranged to provide a variety of options for safe and availability. Controllers and input modules can be simplex, duplex or triplex and outputs can be arranged in I, T or H configurations. It shares the same robust environmental performance as Genius I/O.

|

Approvals |

CE, CSA, FM, UL |

CE, CUL, TUV, UL |

CE, CSA, FM, TUV, UL |

Safety Standards |

EN54-2, IEC 61508 up to SIL 2 for ESD and Fire & Gas, IEC 61511 up to SIL 2, NFPA 72, NFPA 85 |

Category up to Cat 4, IEC 61508 up to SIL 3, IEC 62061 up to SIL CL 3, ISO 13849-1 up to PL e |

IEC 61508 up to SIL 3 |

Network Interfaces |

Modbus TCPIP, SafetyNet P2P for SIL 2 peer-to-peer, Modbus RTU |

Profibus, Profinet |

Genius |

Media |

Copper |

Copper, Fiber |

Copper |

Control Integration |

PAC8000 SafetyNet |

PACsystems |

System 90-70 |

Redundancy |

Controller (for availability), LAN using Fault Tolerant Ethernet technology |

Cable redundancy - MRP |

Modules in H, I or T configuration, |

Software |

IEC 61131 compliant |

Extensive library of safety function blocks, Logic Simulation |

Compiled safety programme |

Hardware Design |

8-channel modules |

Slice I/O, IP 20 |

Block IO |

I/O Scalability |

Up to 64 modules |

from 16 safety I/O points up to 500 safety I/O points |

Based on Genius IO blocks |

Environmental Performance |

-40°C to +70°C operating temperature |

-25°C to +55°C operating temperature |

0°C to +60°C operating temperature |

|

|