SOLUTIONS > Industrial Software > Data Management &

Data Analytics > Proficy Smartsignal

Proficy Smartsignal

Proficy SmartSignal predictive analytics software identifies impending equipment problems early across all process industries and helps avoid unexpected shutdowns and catastrophic failure.

The predictive analytics software identifies what is going to fail, what is the apparent cause of the failure, and what is the priority of the impending failure. And it does so automatically, continuously, and relentlessly, 24 hours/day.

With SmartSignal software, you can spend less time analyzing data and more time acting on it. The software identifies problems well before they happen—often weeks or months before other systems. Its early warnings allow you to shift from costly reactive maintenance to efficient planned maintenance. The result? Improved equipment reliability, asset availability, efficiency, and productivity

SmartSignal software enables you to focus on fixing problems, not looking for them, so you can organize maintenance projects with confidence.

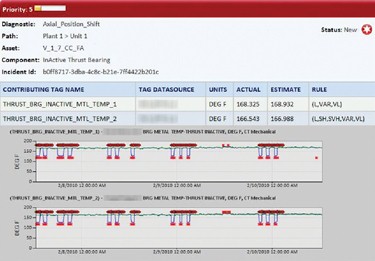

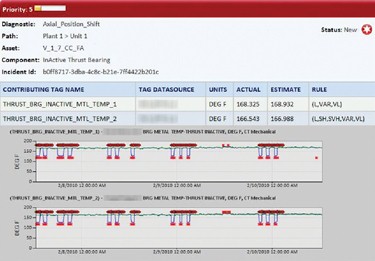

When it sees an impending problem, the SmartSignal software sends a notification to the people who need to know—with a brief summary of the problem, key tags, and values. Multiple alerts are combined into one notification, which narrows the diagnosis and reports urgency. This helps users to quickly resolve pressing equipment issues and avoid more expensive surprises down the line.

The SmartSignal software leverages existing instrumentation, tools, and IT infrastructure. It works on any equipment from any OEM in any service and detects the broadest range of equipment problems across the widest variety of assets, load ranges, and failure modes.

Due to customer demand, we developed the specialized Cycle Watch module for gas turbines (GT’s). This software detects problems that first appear during the stresses of dynamic GT starts and allows you to investigate deviations and perform necessary repairs before the next startup, ensuring units are reliable and ready when needed. The Cycle Watch software captures rapidly changing parameters every ten seconds and enables hundreds of thousands in savings per GT unit each year.

SmartSignal customers report ROI in six to twelve months—and over 95 percent renew their subscriptions every year, attesting to the continuing value and service they receive.

How does the software work?

We started with Similarity-based Modeling (SBM) technology, which was developed more than a decade ago and has become the industry standard in predictive analytics for equipment health. Whereas SBM provides for basic anomaly detection, we now have innovated multiple generations beyond—to also provide advanced diagnostics and prioritizations.

The diagnostic capabilities were built by using shared blind data from GE customers—the world’s largest base of predictive-diagnostic intelligence. After analyzing the data—from hundreds of millions of machine hours and tens of thousands of failures from 12,000 rotating and non-rotating assets—GE was able to identify the fault patterns, in context of operating behavior, that are important to process industries, and incorporate them into the software. Beyond vibration and thermal analysis, the software models all data on all critical rotating and non-rotating equipment. GE uniquely has the years of historical data, across equipment types and a large customer base, to make predictive diagnostics possible. This capability is available through the Shield diagnostic blueprint module.

Consumable and practical

You may choose to purchase a license and use the software yourself. Or you may choose to have us provide some or all of the services you need, remotely or onsite, to implement and maintain the software and monitor your equipment. Our Industrial Performance & Reliability Center, located outside of Chicago, monitors over fifty sites and 4000 assets worldwide every day—over 100,000 signals every ten minutes.

Benefits:

- Improved availability and reliability

- Fewer shutdowns and catastrophic failures

- Reduced damage to critical equipment

- Reduced maintenance and energy costs

- Improved safety

For more information please click on this link